DRILLING HOLES ON PIPES

Drilling on tubes and pipes is always a big task, but now with the modern magnetic drilling machines and the tube clamps, drilling on tubes and pipe is easy and fast.

The following article shows the method of drilling holes on pipes or drilling holes on tubes.

Drilling pipes requires 3 main tools, a tube clamp, a magnetic drilling machine and an annular cutter.

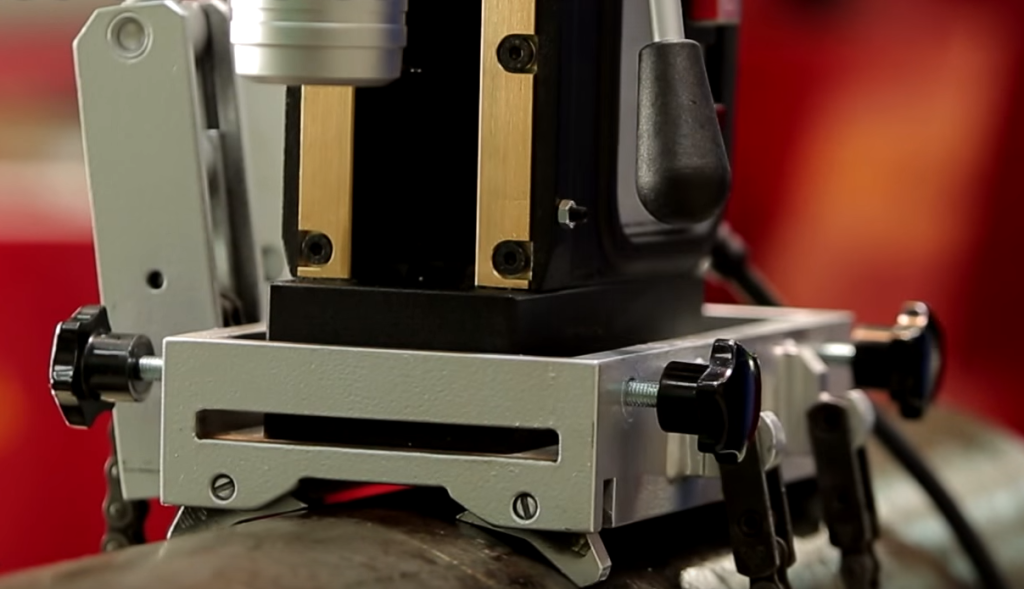

The tube clamping device is a metallic device which is clamped on the tube with an adjustable chain. After clamping the tube clamp the magnetic drilling machine is placed on the device, which gets fix to the tube clamp by switching ON its magnet.

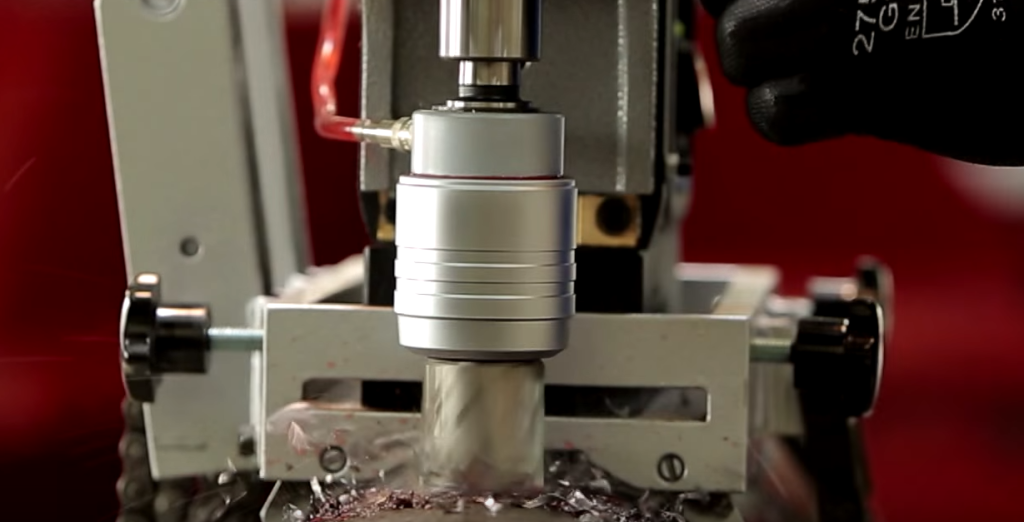

With the help of magnetic drilling machines’ proper RPM the annular cutter makes a perfect hole in the tube.

Generally a HSS annular cutter is used to make holes in tubes and pipes, as the TCT annular cutters has more chances of cutting teeth breakage due to curved surfaces of tubes and pipes.

As annular cutters are hollow there is no dead zone resistance. The cutting takes place only on the periphery of the hole to be made. Annular cutters distribute load equally on the periphery of the hole with its multiple cutting edges, thus the required thrust and energy is also much less comparatively.

Step 1: As per the diameter of the pipe select the correct size of pipe clamp.

The pipe clamp on the left is ideal for tube diameter from 80 – 250 mm and on the right is ideal for diameter from 150 – 500 mm.

Step 2: As per the diameter of the hole select the correct capacity magnetic base drilling machine.

Step 3: Select the correct annular cutter as per the type of pipe or tube material.

Step 4: Clamp the tube clamp device on the tube.

Step 5: Put the magnetic drilling machine on the tube clamp.

Step 6: Insert the annular cutter in the arbor.

Step 7: Switch ON the magnet of the machine and start the motor to drill.

Step 8: Start to drill with min feed, do not crash the cutter on the material while starting to drill.

Step 9: Drill with steady feed and with good amount of drilling lubricant. Result

Result

In just above 9 steps you can make quick holes in pipes and tubes with more accuracy, precision, roundness and finsih as compared to drilling with twist drill bits.

The following video shows more information about the tube clamp and magnetic drilling machine.

For more information, following is the procedure to fix the Pipe Clamp device for pipe drilling:

1. Place the tube clamps’ base (1) on a surface.

2. Clamp the chain tightening attachment (2) using four Allen bolt provided for each attachment.

3. Place the tube clamp device on the pipe then hookup the sprocket chain (3) to the base.

4. Circle the chain (3) around the pipe.

5. Pull the chain (3) from the space between base(1) and the chain tightening attachment (2), put it roundabout gear inside the chain tightening attachment (2)

6. Rotate the adjustment knob (4) on the base for fine adjustment of machine